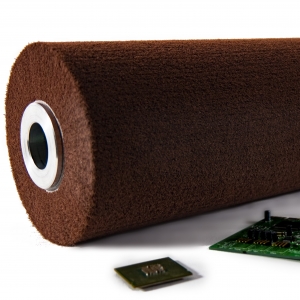

ALUMINIUM OXIDE FLAP ROLLER

This roller is conceived with a tested technological system consisting in non-woven flaps bonded radially to a bakelite core.

Available grits of abrasive nonwoven material are represented with an acronym: AVF which stands for 320 grit aluminium oxide abrasive.

The abbreviation D11 corresponds to the roller hardness and it defines the flaps quantity employed to obtain the required density.

Finer is the grit, higher is the flaps quantity required. The code T10 corresponds to the gap where the aluminum flanges are fitted 670 T10 corresponds to a useful 650 mm of abrasive width.